2025-04-03

What is a clutch?

It is a component that cuts off and transmits power between diesel engines and truck drivetrains. Simply put, it is the use of "separation" and "combination" to transmit an appropriate amount of power. Joining refers to generating frictional torque, while separating refers to releasing frictional torque.

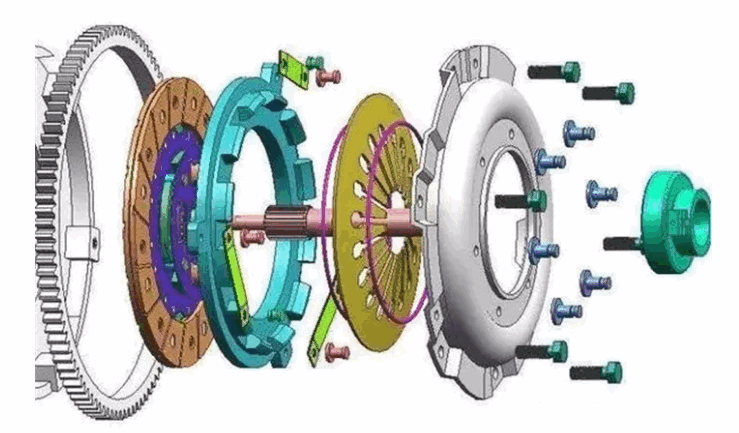

Each clutch is composed of the following parts:

Active parts: flywheel, pressure plate, clutch cover, etc;

Driven parts: driven plate, driven shaft (i.e. the first shaft of the transmission);

Compression part: Compression spring;

Operating mechanism: separation lever, separation lever support column, swing pin, separation sleeve, separation bearing, clutch pedal, etc.

Common faults of clutch

1. Clutch slippage: The truck's power is significantly insufficient, making it difficult to start in low gear and unable to start under heavy loads, while the engine is still running steadily.

2. Incomplete clutch disengagement: When the clutch pedal is pressed to the bottom, the power between the active and passive discs of the clutch cannot be completely cut off, resulting in difficulty shifting gears, gear shifting or inability to stop, and clutch overheating.

3. Clutch vibration: When starting, the whole vehicle shakes, especially when idling or gradually releasing the clutch pedal when shifting to low gear, resulting in continuous impact of the vehicle.

4. Abnormal clutch noise: When the clutch pedal is slightly pressed, the inner end face of the release bearing comes into contact with the release lever, and the clutch immediately emits a continuous "click, click, click" sound; When starting or separating during movement, there is a sound accompanied by shaking.

5. The clutch is pressed heavily:

The clutch linkage mechanisms are too dirty or corroded (mechanical).

Solution: Remove the clutch mechanism for cleaning and maintenance (replace if necessary), inject oil, and adjust the clearance according to the standard.

The hydraulic oil and pipelines of the clutch master and slave pumps are too dirty; Each leather bowl or sealing ring has deteriorated or the oil circuit is blocked.

Solution: Disassemble the clutch master cylinder, slave cylinder, and pipelines, carefully clean them with alcohol, and then blow them clean with high-pressure air, especially the pipelines. Replace the master cylinder and slave cylinder cups and rings, discharge the air, and adjust the clearance according to regulations.

When you feel that the pedal of the clutch is very heavy, the general problem is the release bearing.

Excessive resistance caused by prolonged use, severe wear, and lack of oil. Pressure plate, clutch pressure plate or release bearing failure, which is commonly referred to as the "clutch three piece set", are consumable parts. If there is a malfunction or severe wear, the clutch may become too heavy. And often, excessive clutch weight is a problem of the clutch three piece set. Generally, the service life of a "clutch three piece set" is similar, so it is best to replace it all when replacing it.

(Source: Internet)

Address: No. 8, Xinxing Road, Niutang Industrial Zone, Changzhou, Jiangsu, China

Tel:+86 519-86391433 +86 519-86390759

Fax:+86 519-86397329

E-mail:sales@hc-bearing.com

service@hc-bearing.com

info@hc-bearing.com

Website: www.hc-bearing.com

Smart Catalog