Technological Process

Selected high-quality steel is used as raw material, and undergoes rigorous chemical composition analysis and mechanical property testing to ensure that the material meets production requirements.

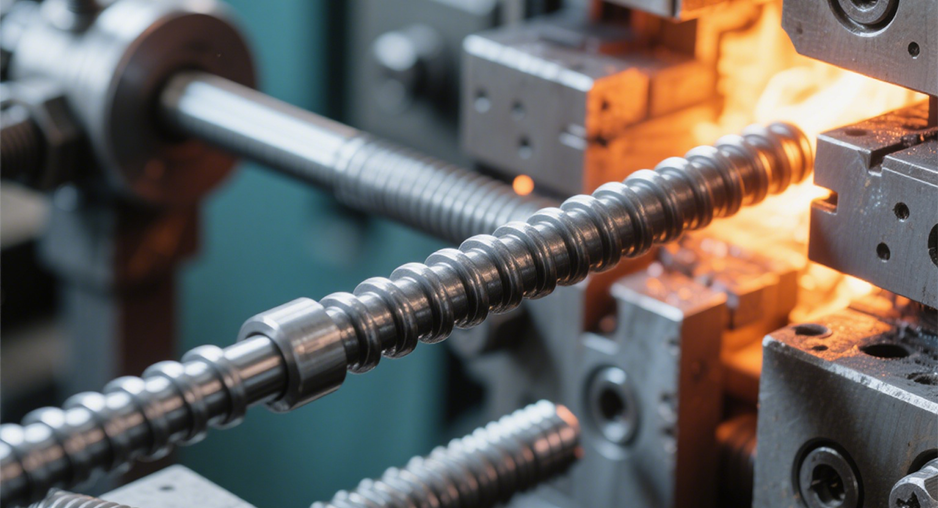

Process raw materials into the basic shape of rolling needles through cold heading or hot rolling processes. This process requires precise control of temperature and pressure to ensure the dimensional accuracy and surface quality of the needle rollers.

Quench and temper the formed needle rollers to enhance their hardness and wear resistance, while maintaining appropriate toughness to ensure long-term stable operation of the bearings.

By using processes such as grinding and polishing, the dimensional accuracy and surface smoothness of the rolling needle can be further improved to meet the needs of different application scenarios.

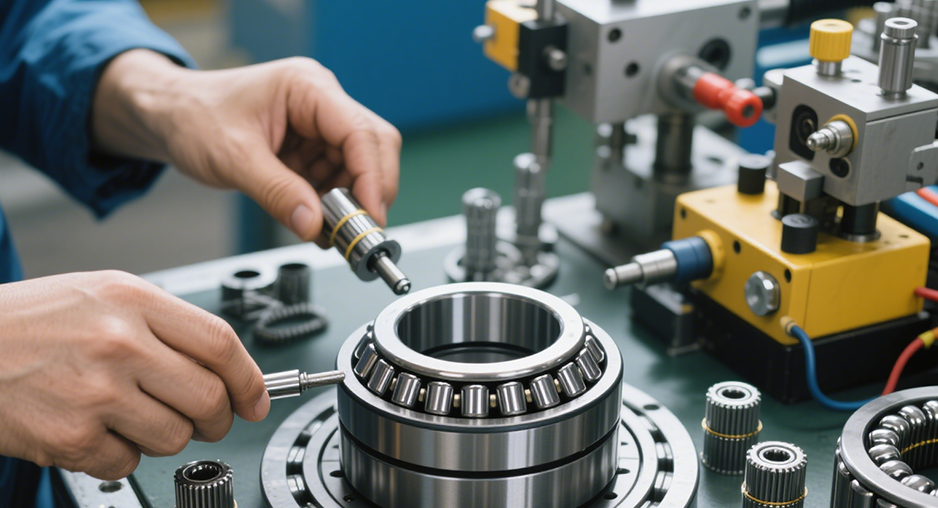

Accurately assemble components such as needle rollers, retainers, and inner and outer rings into complete bearings, followed by rigorous quality testing, including rotational resistance testing, noise testing, and vibration testing, to ensure that each bearing meets performance standards.

Bearings that have passed strict inspection will be properly packaged, accompanied by detailed product information and quality certification documents, and ready to be shipped to customers.

Address: No. 8, Xinxing Road, Niutang Industrial Zone, Changzhou, Jiangsu, China

Tel:+86 519-86391433 +86 519-86390759

Fax:+86 519-86397329

E-mail:sales@hc-bearing.com

service@hc-bearing.com

info@hc-bearing.com

Website: www.hc-bearing.com

Business Consultation

Smart Catalog